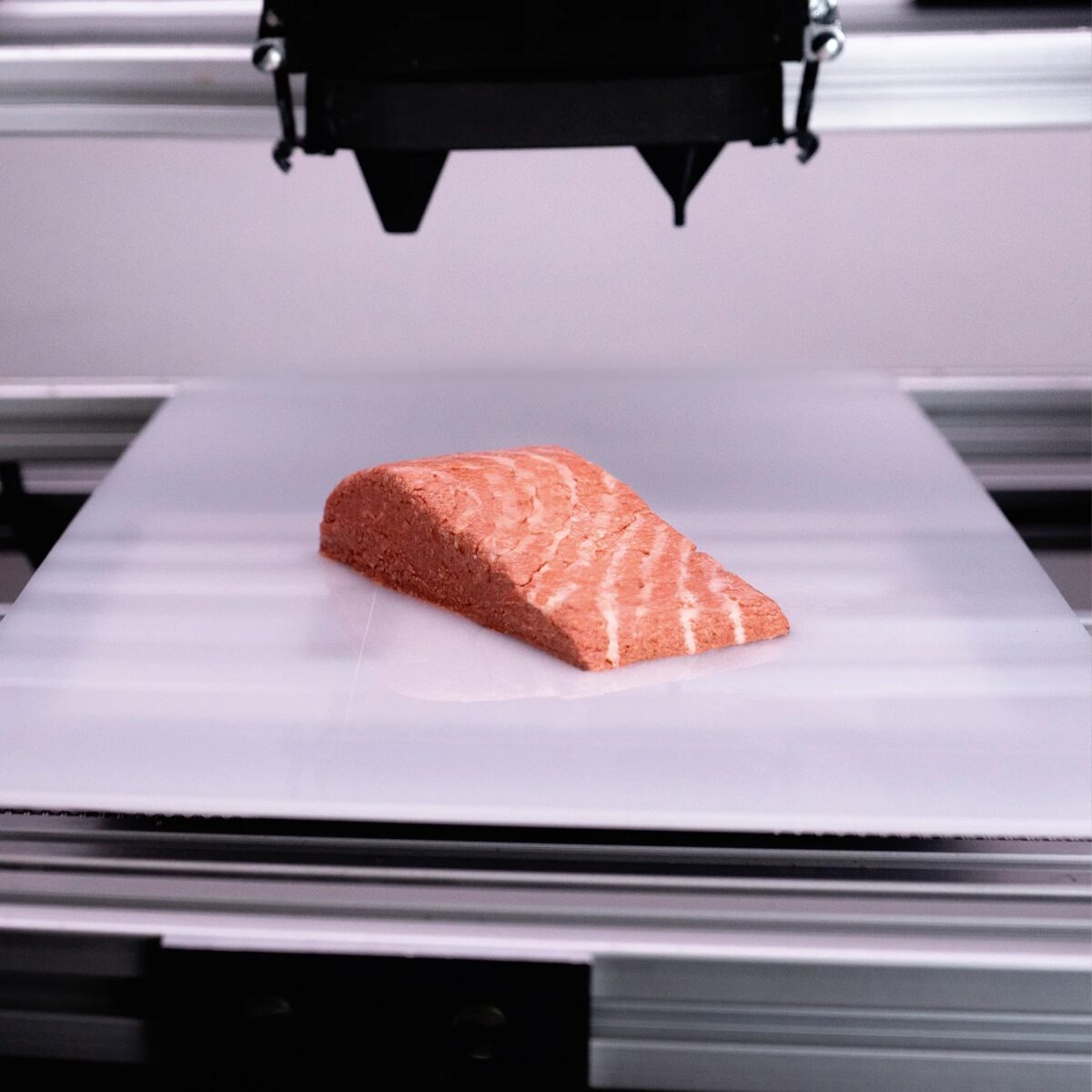

What’s thought to be the world’s first 3D printed vegan salmon filet has hit supermarket shelves in Germany and Austria.

Austrian plant-based seafood company Revo Foods has made the filet – named “THE FILET – Inspired by Salmon” – using algae, pea protein, and mycoprotein from Swedish company Mycorena.

Revo Foods says its latest creation has the same “flakiness and juicy fibers” that people would expect from a salmon fillet. According to Food Navigator, the vegan filet has high protein and omega-3 content, giving it the top score of A in Europe’s nutrition labeling system Nutriscore.

A number of vegan salmon filets are already available in supermarkets, including Plant Pioneers No Salmon Fillets in Sainsbury’s and Vivera’s Plant Salmon Style Fillets in Tesco’s. Israeli company Plantish will launch it’s realistic filet at pop-up locations in 2024. A filet by Canada’s New School Foods will be available in restaurants in North America this year.

But Revo Foods’ filet will be the first made using 3D printing technology.

Game-changing

Revo Foods used 3D MassFormer technology, for which it has a patent pending. It is a continuous production process that “allows the recreation of highly complex plant protein structures that resemble the muscle strands of salmon or tuna,” Robin Simsa, CEO of Revo Foods, told Vegconomist.

3D food printers work by loading them up with ingredients made into a gel, paste, liquid, or powder. These are then extruded through food-grade nozzles layer by layer. One of the big advantages of it is that food can be customised in terms of texture, flavour, and nutrition.

Other companies such as Redefine Meat have been using the technology to create foods like beef flank and pulled pork without using any animal products. Revo Foods has made 3D printed products such as smoked salmon slices since 2020.

“With the milestone of industrial-scale 3D food printing, we are entering a creative food revolution,” said Simsa. “This new process is a gamechanger for meat alternatives, making it possible to create a new category of authentic products such as vegan steaks and filets.”

Low impact food

One major environmental benefit of 3D printed plant-based seafood is the number of fish it could save from being harvested from the sea. According to Revo Foods, its products have saved nearly 19,000 fish so far.

Researchers are also investigating how 3D printed food could lower the environmental footprint of food production. Utilising food waste to create the edible “inks” for the printers is a particularly promising option. Food waste accounts for six percent of global carbon emissions.

But the ingredients Revo Foods is using already has a significantly lower carbon footprint than seafood. According to data from CarbonCloud’s climate hub, which calculates food supply chain emissions, mycoprotein beats low-impact peas and soy as plant-based protein sources for emissions per kilogram.